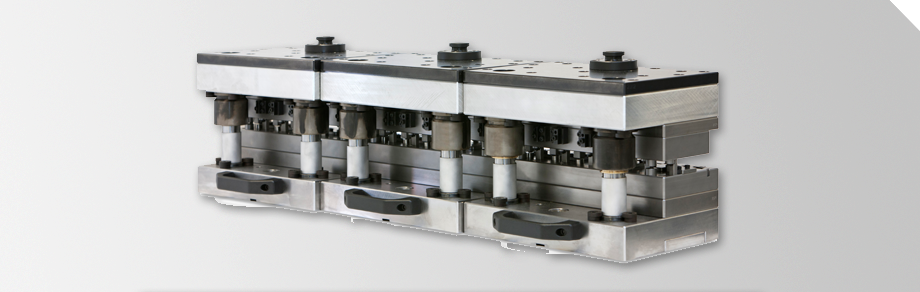

Stamping Techniques

Blanking, bending, coining or drawing of parts up to 1.5 mm material thickness is our core competence. Our systems are optimized for these applications. Within these applications and with our assistance, you can expand the limits of what has been feasible so far:

Stamping with smart impuls s®:

- Improved clean cut ratio

- Improved straightness of edges

- Improved flatness of the stamping part

- Reduced stamping burr

Bending with smart impuls b®:

- Reduced fissuring of small radiuses with hard, brittle materials

- Improved process capabilities of bending angles

- Programmable modification of bending angles

Coining with smart Impuls p®:

- Reduced forming power requirement, higher forming degree

- Reduced stresses in the coining zone

- Reduced brittleness in the forming area

Drawing with smart Impuls z®:

- Process validation currently in progress